Evaluation of the Acoustic ScalePreventer Test Results for Heating Furnaces£º¡¡

Acoustic ScalePrevent Technology is a physical ScalePrevent method. The Acoustic Scale Preventer consists of a Generator and fewTransducers. The pulse signals generated by the Generator are transmitted to the Transducers, where they are converted into acoustic oscillations. These oscillations propagate to the heat exchange surfaces, producing a descaling effect. This device is an online descaling solution for heat exchange equipment (e.g., boilers, heat exchangers, condensers, and heating systems).

The acoustic oscillations generated by the device are transmitted through the metal components of the heat exchange equipment to the heat transfer surfaces and the water medium, achieving the following effects:

1. Continuous descaling: Scale deposits on the heat exchange tubes are continuously peeled off, establishing a dynamic balance between descaling and scaling. This maintains scale thickness below 0.5 mm, thereby preventing scale.

2. Mineral crystallization: Acoustic waves transmitted to the water medium induce direct crystallization of mineral salts in the water, forming precipitated powder.

At the Bai-1 Metering and Transfer Station, severe scaling occurred in the oil coil tubes of the heating furnace during operation. The inlet pressure of the oil coils exceeded 1.8 MPa, leading to increased wellhead backpressure and operational challenges (Figure 1). Acid cleaning of the oil coils was required every three months, causing significant disruptions to normal production.

Figure 1: Pre-installation

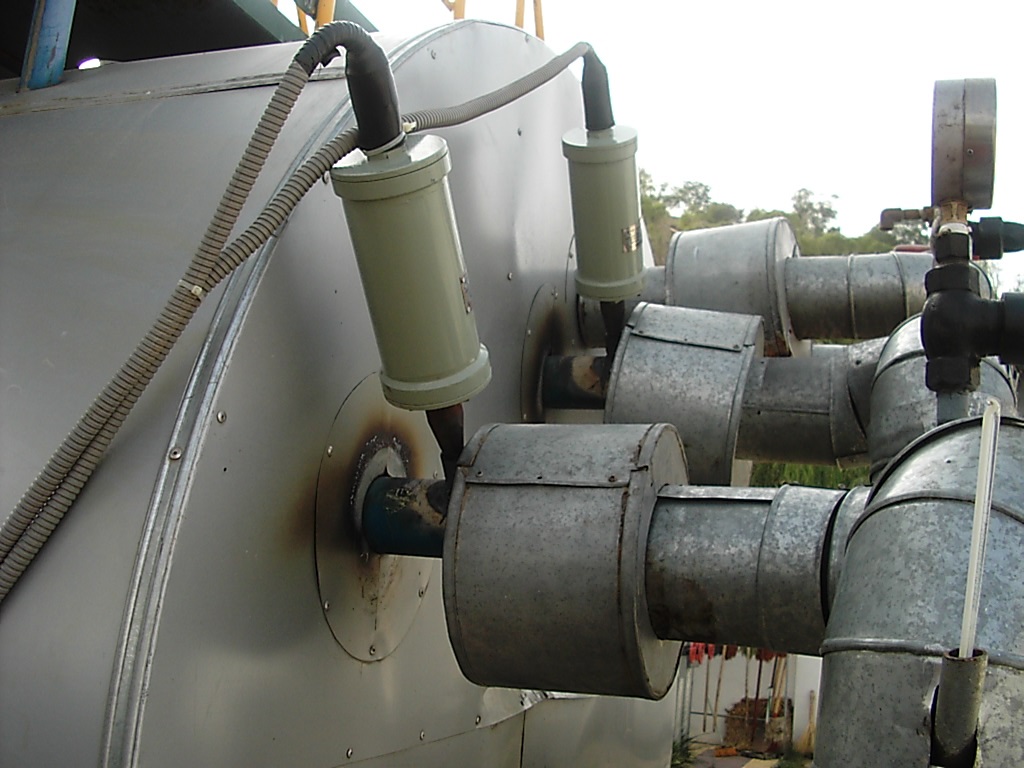

To mitigate scaling and ensure unimpeded oil flow, Acoustic ScalePreventer were installed on two heating furnaces in August 2005, following on-site evaluations by the Production Operations Department of the Fourth Oil Production Plant, the Oil Production Technology Research Institute, and Shanxi Tech-Top Technology Development Co., Ltd. (Figure 3). After acid cleaning (Figure 2), the devices were activated. To date, they have operated continuously for over 9 months, maintaining the oil coil inlet pressure below 0.5 MPa. Inspections of the oil coils revealed no scale (Figure 4), confirming the effectiveness of the Acoustic ScalePreventer.

Results:

- Eliminated the need for acid cleaning, reducing operational costs.

- Improved thermal efficiency and extended the service life of the heating furnaces.

- Simplified field management and reduced maintenance workloads.

Recommendation: Acoustic Scale Preventer should be widely deployed in heating furnaces with severe scaling issues.

Figure 2: Post-acid cleaning

Figure 3: Installation example

Figure 4: Operational results

Oil Production Technology Research Institute, Fourth Oil ProductionPlant,Changqing Oil Field,CNPC

May 25, 2006

|